Series

Ftncore ForPolymer Series

ForPolymer series of Fortune Core specializes in R&D of electrospinning technology, air filtration and purification materials as well as their manufactures and sales. At present ForPolymer series majors in production and sales of air filtration products, filtering materials and filters for civil or industry use, purification devices and accessories. With owned plants and workshops for large-scale patented electrospinning and purification manufacturing system ForPolymer series of Fortune Core has gradually formed a comprehensive enterprise standard operation process and distribution channels.

Our goal

Drive new applications for electrospinning technology and bring leading designs from laboratory to manufacturing of large-scale production of washable nanofiber air filter replacements, nanofiber window screens, nanofiber fruit bags and washable nanofiber filtered protective mask, etc.

Comparing to traditional filter materials, nanofiber products from Fortune Core are Pure physical filter material characterized by lower resistance, higher efficiency, washable and reusable features which can be widely used in face masks, window screens, air conditioners, air purifiers, fresh air systems, fruit bags and other related filtering fields. Meanwhile, our research and development team are making great progress in solutions for personal and professional use including facial treatment mask, diaper, HVAC, room cleaning and filtration of specific medical applications.

Concept

The Principle of Electrospun Nanofibers

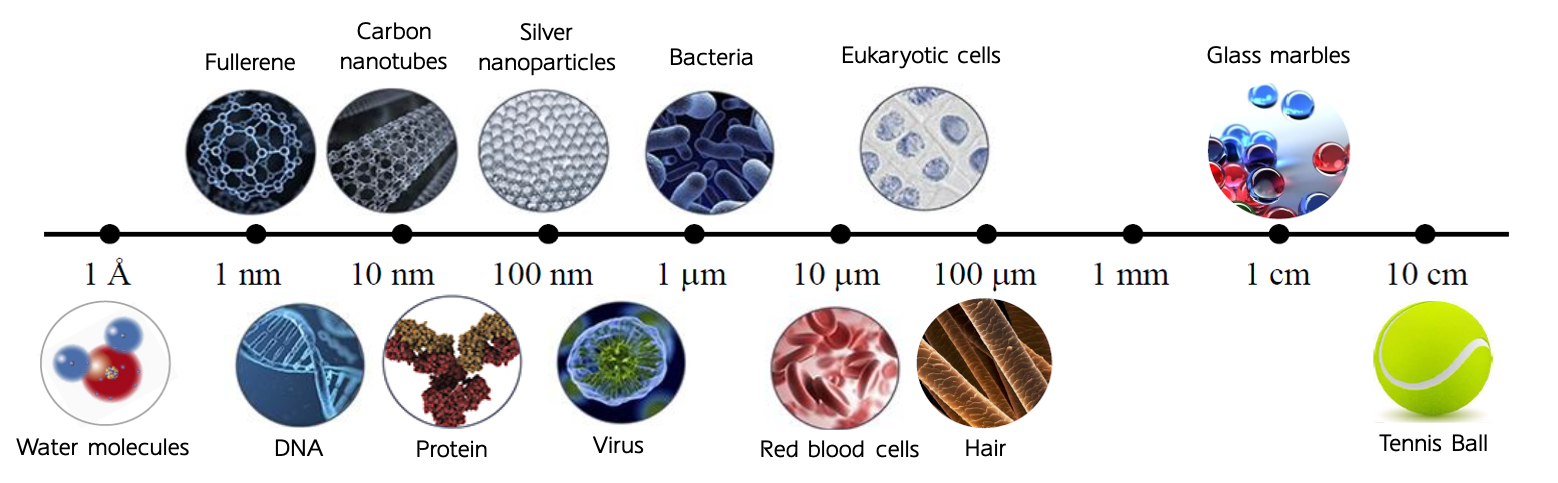

Nano/Nanometer

When we mention nano, actually we are saying nanometer. Nanometer is a length unit, which is one billionth of one meter.

Fiber

It is a substance consisting of continuous or discontinuous filaments. An element that gives texture or substance essential structure or character of one substance.

Nanofiber

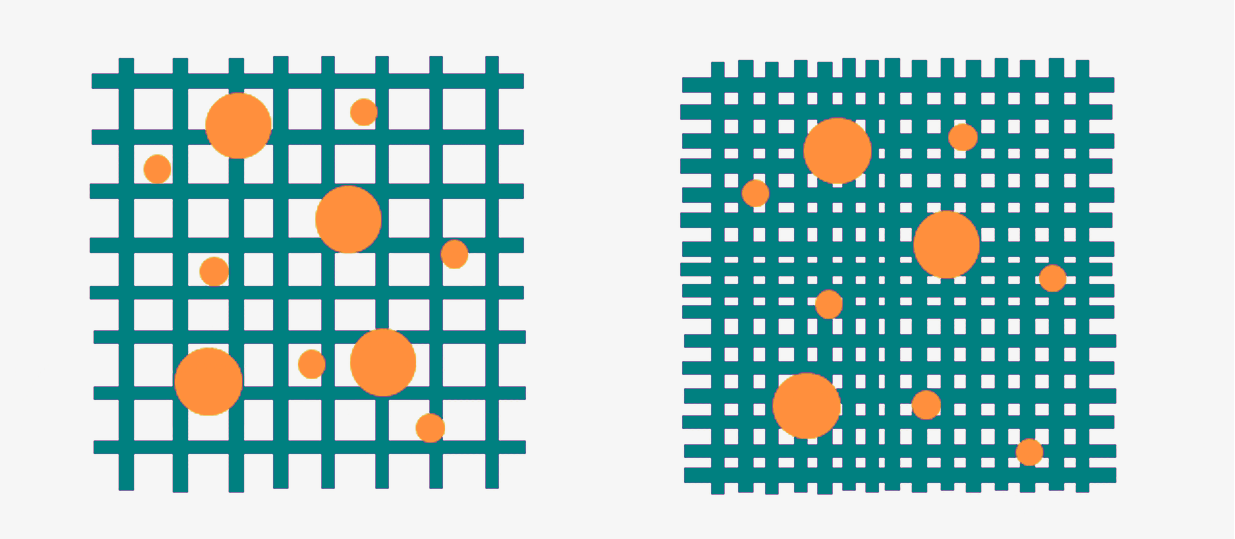

As the linear material with a certain aspect ratio of nano scale, usually it refers to fibers with diameters less than 100 nanometers. In the textile industry, this definition is often extended to include fibers as large as 1000 nanometers diameter.

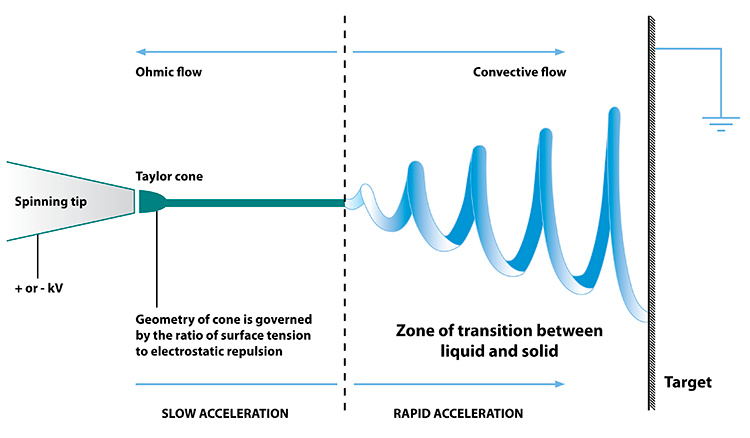

Electrospinning Technique

It is a method of producing fibers with a diameter of 50-100 nanometers by controlling the electric field and stretching the charged strands of polymer solution or polymer melt.

Thin and Light

Huge Specific Surface

Tiny Pore Size

Highly Customizable

ForPolymer Nanofiber

Fortune Core produces nanofiber material on an industrial scale, ForPolymer media composed of ultrafine fibers with diameters down to tens of nanometers are capable to physically block viruses (0.1μm). It is characterized by lower resistance, higher filter efficiency, moisture resistance compared to commonly used meltblown.

By adjusting the composition and nanostructures, the ForPolymer material is ready to achieve other necessary functions beyond virus blocking, such as antiviral, washable and reusable, degradable and compostable, etc.

Process

The Workmanship of Basic ForPolymer Media

Solution

Polymer with various functions is prepared as solution.

Nano Core

The solution was stretched into fibers by a 100kV electric field.

Carrier

20g-40g spunbond or other material can be the carrier.

Base Roll

An individual material layer that contain a nanofiber layer.

Laminated

Thermal bonding of the base roll and cover layer together.

Finished Product

Corresponds exactly to the requirements of the end customer.

Pros

ForPolymer Series Compared to Similar Products

What sets us aside from other competitors?

ForPolymer-REU

VS. PP Meltblown

- Higher filtration efficiency

- Lower resistance

- Long lasting

- Washable and reusable

ForPolymer-BIO

VS. PLA Meltblown

- Heat-resistant

- Resistant to moisture

- Standard-compliant

- Biodegradable and compostable

ForPolymer-COS

VS. Traditional Facial Mask

- Dry sheet, easy to carry

- Nano essence, deep skin treatment

- No preservatives

- Advanced absorptive capacity